| View previous topic :: View next topic |

| Author |

Message |

G~FORCE

Joined: 18 Mar 2006

Posts: 75

Location: OREGON

|

Posted: Sat Apr 01, 2006 11:26 pm Post subject: long wordy post about wear ring clearance.........HELP! Posted: Sat Apr 01, 2006 11:26 pm Post subject: long wordy post about wear ring clearance.........HELP! |

|

|

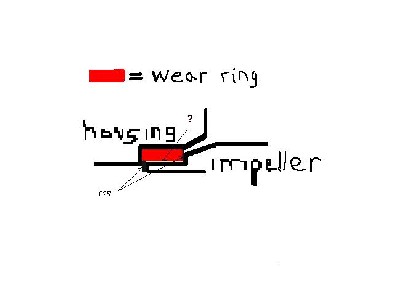

| i am trying to figure out finally what a pump is doing when it pumps and i have some questions regarding clearances. the glass boat guys are always talking about the wear ring clearance on "the shoulder" but when i look at my impeller i see two places a "shoulder" could be clearanced. one is the very most forward edge of the impeller that penetrates the housing the furthest forward. this would be measured in through the hand hole with a feeler. the other is the next step rear of that edge where the wear ring butts up against the impeller. this one would be measured from the outside of the pump with the bowl removed. the final clearance is the outer edge of the impeller to inner of the wear ring. so they say .025" is good for the step, and i think they are saying .025" also for the side clearance. however, they also talk about a plastic ultimate wear ring which to me looks as if it has steps at both ends>? so which is it that gets the .025"? also they say to adjust the step clearance use shims or cut the front of the hub on the impeller, but being that the shaft is tapered how can you shim it or cut it? wont it end up being too tight or loose on the shaft? thanks- g

|

|

| Back to top |

|

|

MidwetJetSprint

Joined: 29 Jul 2005

Posts: 160

Location: Chicago Metro

|

Posted: Sun Apr 02, 2006 7:39 am Post subject: Posted: Sun Apr 02, 2006 7:39 am Post subject: |

|

|

There is this guy who lives in Oshkosh Wis he has found a way and makes a PVC wear rings.The guy is a former Jet pump test Engineer for the Big Black Marine engine.He even has a barring swap for Berkeley the guy is awsome.

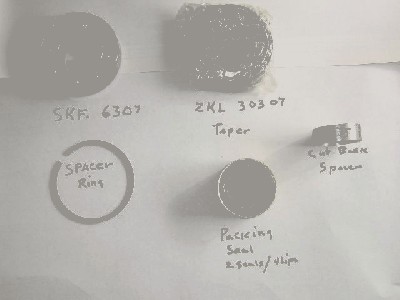

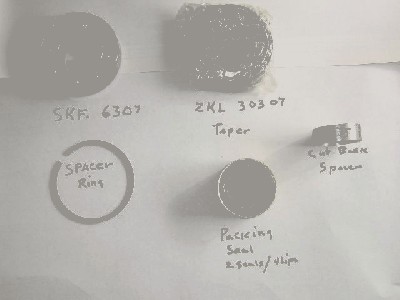

| Description: |

|

| Filesize: |

43.98 KB |

| Viewed: |

1557 Time(s) |

|

_________________

Old Age and Treachery always Overcome Youth and Skill! |

|

| Back to top |

|

|

G~FORCE

Joined: 18 Mar 2006

Posts: 75

Location: OREGON

|

Posted: Sun Apr 02, 2006 10:44 am Post subject: Posted: Sun Apr 02, 2006 10:44 am Post subject: |

|

|

| i think my wear ring is ok, i just want to verify clearances while i have it apart and not do too much to the pump. if i was to do any real work i think i would just blueprint the whole unit. the gap at the rear of the wear ring to step on impeller is big on mine, about .120" this seems weird

|

|

| Back to top |

|

|

AR

Joined: 23 Jun 2005

Posts: 181

Location: Iowa, USA

|

Posted: Mon Apr 03, 2006 7:21 pm Post subject: Posted: Mon Apr 03, 2006 7:21 pm Post subject: |

|

|

If you are saying that the clearance from the very rear most of the impeller at the wear ring surface to the step on the wear ring is .120, that is to much.

If you are running an "Ultimate" wear ring I'd shoot for around .015 with the impeller nut tight. If you don't have any shims on the shaft between the impeller and the step on the shaft then you are going to have to use a lath and turn off some of the hub on the side of the impeller that goes on the shaft first.

All that does is let the impeller slide further onto the shaft and into the wear ring. Less clearance between the impeller and the step on the wear ring.

If you set the wear ring clearance WITHOUT the nut being torqued it will definitely tighten up when the nut is tight. You can get the clearance close without the nut tight, then tighten it and the motor won't turn over.

I like the Ultimate wear ring because it's easy to change if you are trying different impellers that have different wear ring sizes. It also seems to be kind of self healing. I've run one in a silty, shallow river for a couple years without any problems.

http://hi-techperformance.com/images/Ultimate_Wear_Ring.jpg

______-

Last edited by AR on Tue Apr 04, 2006 7:49 am; edited 1 time in total |

|

| Back to top |

|

|

AR

Joined: 23 Jun 2005

Posts: 181

Location: Iowa, USA

|

Posted: Mon Apr 03, 2006 7:34 pm Post subject: Posted: Mon Apr 03, 2006 7:34 pm Post subject: |

|

|

Hey, MidwetJetSprint

I'd think that the way that little girl jerks around, she'd have one hell of a headache !

It even gives me one !

______

|

|

| Back to top |

|

|

G~FORCE

Joined: 18 Mar 2006

Posts: 75

Location: OREGON

|

Posted: Mon Apr 03, 2006 7:43 pm Post subject: Posted: Mon Apr 03, 2006 7:43 pm Post subject: |

|

|

| she doesnt notice because her boobs hurt so much. thanks ar, i think i get it and i think i can run my existing wear ring. any comment on side clearance to the impeller?

|

|

| Back to top |

|

|

AR

Joined: 23 Jun 2005

Posts: 181

Location: Iowa, USA

|

Posted: Mon Apr 03, 2006 7:56 pm Post subject: Posted: Mon Apr 03, 2006 7:56 pm Post subject: |

|

|

I like .015 to .020 all the way around on a fresh set-up and don't worry about it, if it don't cavitate !

__

Last edited by AR on Mon Apr 03, 2006 9:31 pm; edited 1 time in total |

|

| Back to top |

|

|

MidwetJetSprint

Joined: 29 Jul 2005

Posts: 160

Location: Chicago Metro

|

Posted: Mon Apr 03, 2006 8:14 pm Post subject: Posted: Mon Apr 03, 2006 8:14 pm Post subject: |

|

|

AR lol ya she makes my eyes hurt after awhile on my way back from Denver I passed right Thur town looks like some of the rivers where up the little sunk east of town looks interesting Cheers Steve

_________________

Old Age and Treachery always Overcome Youth and Skill! |

|

| Back to top |

|

|

AR

Joined: 23 Jun 2005

Posts: 181

Location: Iowa, USA

|

Posted: Mon Apr 03, 2006 9:21 pm Post subject: Posted: Mon Apr 03, 2006 9:21 pm Post subject: |

|

|

| Quote: | | on my way back from Denver I passed right Thur town looks like some of the rivers where up the little sunk east of town looks interesting |

The Rivers here are all up right now ! They're dumping a lot of water at the damn which is north of town. If you were on the interstate, the Damn is a couple miles north as you crossed the river.

The two south of town will be 1 to 2 feet most of the Summer in the deep spots, real twisty,and a lot of wood. I've ridden them on a Snowmobile but not by boat.

Oh, there is a Shaker Bar about 100 yards off the river if you're into that stuff. They have to be out in the County like that to be all nude !

North of town and north of the damn in the river channel it's all good for 40 miles. Just real twisty and a little wood. I've Snowmobiled that too.

The Skunk that you saw is mostly dried up and 2' or 3' wide in the summer.

Put that boat together and come on over.

You could boat from the north thur town to the south if a couple 6 foot damns don't bother you.

________

|

|

| Back to top |

|

|

AR

Joined: 23 Jun 2005

Posts: 181

Location: Iowa, USA

|

Posted: Mon Apr 03, 2006 9:25 pm Post subject: Posted: Mon Apr 03, 2006 9:25 pm Post subject: |

|

|

Hey, G~FORCE

Sorry about steeling you're post !

______

|

|

| Back to top |

|

|

SouthIdahoGary

Joined: 15 Jun 2005

Posts: 295

Location: Wilder, ID, USA

|

|

| Back to top |

|

|

AR

Joined: 23 Jun 2005

Posts: 181

Location: Iowa, USA

|

Posted: Mon Apr 03, 2006 11:05 pm Post subject: Posted: Mon Apr 03, 2006 11:05 pm Post subject: |

|

|

Gary,

I used that kind of a deal some time ago.

You may think I'm nuts but those Ultimate wear rings have got me spoiled.

You push'em in with your thumbs, set'em with a rubber hammer, check the shims a couple times and get wet !

To take'em out, use a little screwdriver and you fingers. You can take them in and out several times and don't hurt anything. No heat or cold required !

I can change a wear ring and impeller, and have it set up in less than 30 minutes and my beers still cold.

And for the record, I don't sell them, have stock in the company or get any special deals on the ones I buy.............

________

|

|

| Back to top |

|

|

G~FORCE

Joined: 18 Mar 2006

Posts: 75

Location: OREGON

|

Posted: Mon Apr 03, 2006 11:28 pm Post subject: Posted: Mon Apr 03, 2006 11:28 pm Post subject: |

|

|

| AR wrote: |

And for the record, I don't sell them, have stock in the company or get any special deals on the ones I buy.............

________ |

oh god dont start one of these here!

hey gary thanks as always you got the answer and even pics to prove it! so it looks like they want .025" at both ends of the wear ring but still not mention of the radial clearance? also if my rear step clearance is wider than my front then i need to cut the hub and the outer edge of the impeller, if the back is tight and the front is loose then i need to cut the outer step of the impeller to make the wear ring surface wider. right?

|

|

| Back to top |

|

|

G~FORCE

Joined: 18 Mar 2006

Posts: 75

Location: OREGON

|

|

| Back to top |

|

|

SouthIdahoGary

Joined: 15 Jun 2005

Posts: 295

Location: Wilder, ID, USA

|

Posted: Tue Apr 04, 2006 7:49 am Post subject: Posted: Tue Apr 04, 2006 7:49 am Post subject: |

|

|

Radial clearance .025 TOTAL (.0125 per side=your yellow area). The inside diameter of the wear ring MINUS the outside diameter of the impeller that goes into the wear ring should be .025.

Here is a link with some good Tech Tips

http://www.rexmar.com/page115.html

IMHO the "rear" axial clearance (rear of wear ring to front of impeller "shoulder") is basically unimportant. If the rear clearance is "large" and the front clearance is OK, then leave it alone. The front clearance controls the amount of "leakage".

If the back clearance is smaller than the front then that COULD be trouble, but only if it is less than .010....once again IMHO.

_________________

"faster, Faster, FASTER until the thrill of speed overcomes the fear of DEATH"#163 "Tuff-n'-Nuff" |

|

| Back to top |

|

|

|