| View previous topic :: View next topic |

| Author |

Message |

G~FORCE

Joined: 18 Mar 2006

Posts: 75

Location: OREGON

|

|

| Back to top |

|

|

G~FORCE

Joined: 18 Mar 2006

Posts: 75

Location: OREGON

|

Posted: Wed Apr 05, 2006 10:15 pm Post subject: Posted: Wed Apr 05, 2006 10:15 pm Post subject: |

|

|

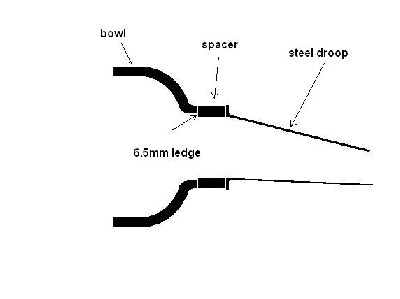

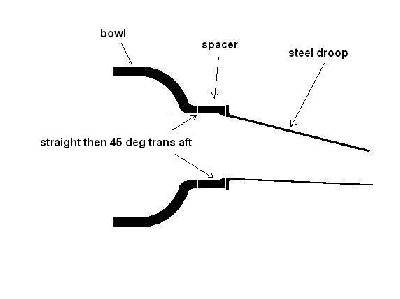

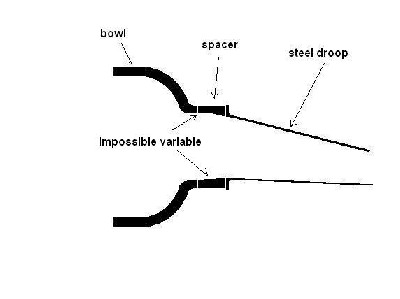

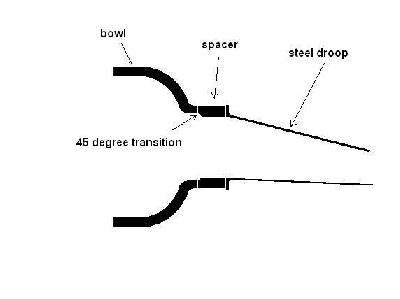

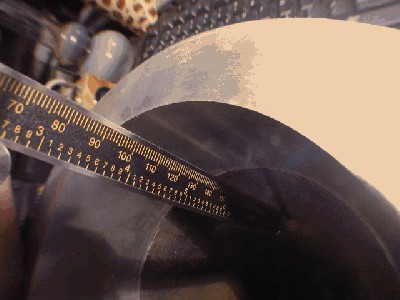

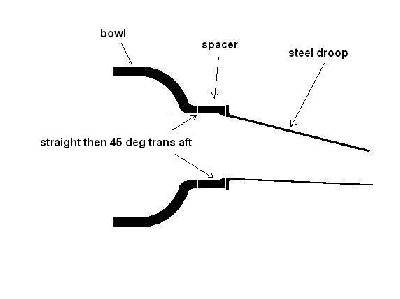

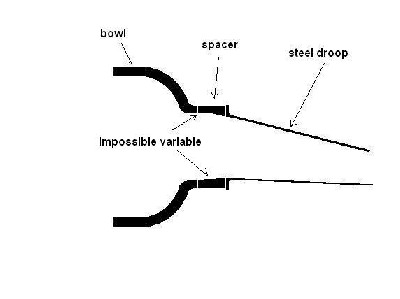

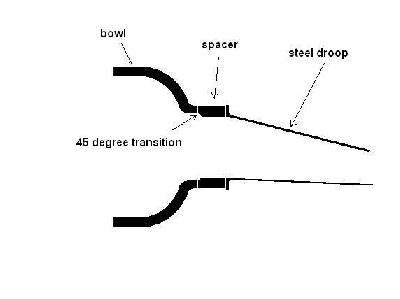

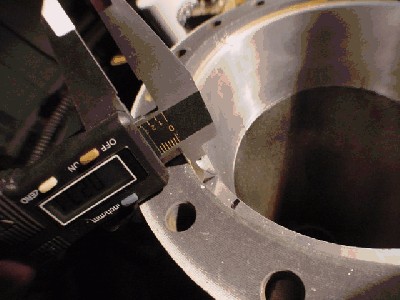

the options?-

| Description: |

|

| Filesize: |

14.71 KB |

| Viewed: |

997 Time(s) |

|

| Description: |

|

| Filesize: |

13.85 KB |

| Viewed: |

1090 Time(s) |

|

| Description: |

|

| Filesize: |

13.49 KB |

| Viewed: |

1111 Time(s) |

|

|

|

| Back to top |

|

|

G~FORCE

Joined: 18 Mar 2006

Posts: 75

Location: OREGON

|

Posted: Wed Apr 05, 2006 10:16 pm Post subject: Posted: Wed Apr 05, 2006 10:16 pm Post subject: |

|

|

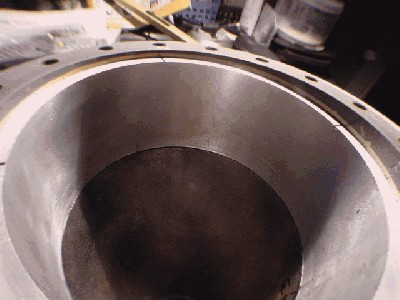

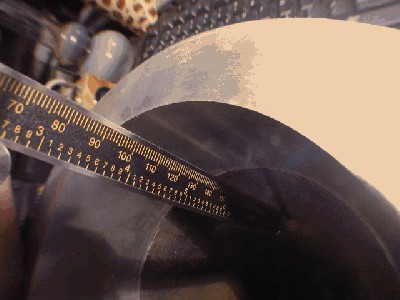

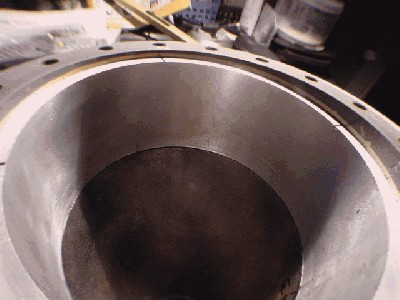

the stuff

| Description: |

|

| Filesize: |

60.77 KB |

| Viewed: |

1139 Time(s) |

|

| Description: |

|

| Filesize: |

61.06 KB |

| Viewed: |

998 Time(s) |

|

| Description: |

|

| Filesize: |

60.6 KB |

| Viewed: |

1003 Time(s) |

|

|

|

| Back to top |

|

|

G~FORCE

Joined: 18 Mar 2006

Posts: 75

Location: OREGON

|

Posted: Wed Apr 05, 2006 10:18 pm Post subject: Posted: Wed Apr 05, 2006 10:18 pm Post subject: |

|

|

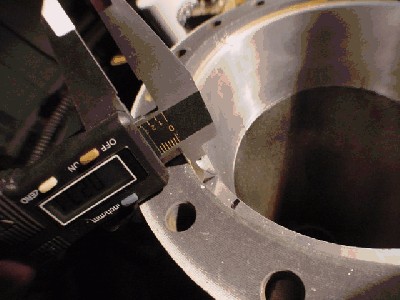

stuff.......

| Description: |

|

| Filesize: |

60.65 KB |

| Viewed: |

1059 Time(s) |

|

| Description: |

|

| Filesize: |

61.78 KB |

| Viewed: |

1023 Time(s) |

|

| Description: |

|

| Filesize: |

60.21 KB |

| Viewed: |

1029 Time(s) |

|

|

|

| Back to top |

|

|

G~FORCE

Joined: 18 Mar 2006

Posts: 75

Location: OREGON

|

Posted: Wed Apr 05, 2006 10:22 pm Post subject: Posted: Wed Apr 05, 2006 10:22 pm Post subject: |

|

|

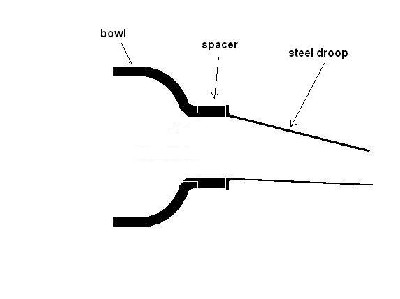

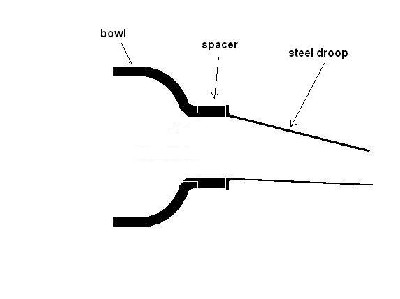

| oh ya i forgot to mention i will use a wedge i think its 5 deg. i assume it will be installed after the space at the droop flange,.??

|

|

| Back to top |

|

|

Cavefish

Joined: 18 Jun 2005

Posts: 130

Location: Klamath, CA, USA

|

Posted: Thu Apr 06, 2006 8:03 am Post subject: Posted: Thu Apr 06, 2006 8:03 am Post subject: |

|

|

I think the best way is the impossible angle version, try and lose the 6.5 mm over the length of the spacer. If you don't have a way to to that, how about put the 45 degree ridge at the snoot end, then blend back to bowl diameter with bondo or some kind of JB weld type stuff? Maybe round the top of the ridge a little first with a drum sander on a drill.

I guess you need a lathe that you could angle the bed to actually cut the inside at the angle you need. Do they even make such a thing???

Interesting project!

_________________

-Jesse |

|

| Back to top |

|

|

G~FORCE

Joined: 18 Mar 2006

Posts: 75

Location: OREGON

|

Posted: Thu Apr 06, 2006 8:59 am Post subject: Posted: Thu Apr 06, 2006 8:59 am Post subject: |

|

|

| well the reason i am so curious is that i had read mention of the spacers job being to stabilize the column of water by straightening it and letting it "settle" in a non tapered area before cramming down the neck of the nozzle. this would count against the impossible variable style......

|

|

| Back to top |

|

|

AR

Joined: 23 Jun 2005

Posts: 181

Location: Iowa, USA

|

Posted: Thu Apr 06, 2006 9:01 am Post subject: Posted: Thu Apr 06, 2006 9:01 am Post subject: |

|

|

You need a friend with a lathe !

Then the hardest part is getting the angle right. Each width spacer takes

a different angle.

With two different size openings it makes it impossible to stack spacers

when you're testing.

Is it possible to make the nozzle opening the same size as the bowel ?

Just a thought. . . . .

______

|

|

| Back to top |

|

|

G~FORCE

Joined: 18 Mar 2006

Posts: 75

Location: OREGON

|

Posted: Thu Apr 06, 2006 9:05 am Post subject: Posted: Thu Apr 06, 2006 9:05 am Post subject: |

|

|

| your thought is interesting though because i could leave the spacer as is and bondo in the bowl exit insted. this would give me smoothness and the straight column of h20, however it would be necking down the entire system earlier...... also it would make it harder to use the wedges.

|

|

| Back to top |

|

|

AR

Joined: 23 Jun 2005

Posts: 181

Location: Iowa, USA

|

Posted: Thu Apr 06, 2006 9:23 am Post subject: Posted: Thu Apr 06, 2006 9:23 am Post subject: |

|

|

The nozzle itself would be the deal.

How did you end up with different sizes to begin with ?

.

|

|

| Back to top |

|

|

G~FORCE

Joined: 18 Mar 2006

Posts: 75

Location: OREGON

|

Posted: Thu Apr 06, 2006 11:48 am Post subject: Posted: Thu Apr 06, 2006 11:48 am Post subject: |

|

|

| not sure how they are different. must be a different bowl than was originally for the nozzle. i think i like the idea of filling the bowl instead of boring the spacer. this makes sense to me.

|

|

| Back to top |

|

|

G~FORCE

Joined: 18 Mar 2006

Posts: 75

Location: OREGON

|

Posted: Thu Apr 06, 2006 11:56 pm Post subject: Posted: Thu Apr 06, 2006 11:56 pm Post subject: |

|

|

ok this seems like the best idea. i wish i had thought of it before i bought the piece, i could have got a longer chunk of al. i think if i do this i will make it out of plastic like an inner ring.

| Description: |

|

| Filesize: |

11.84 KB |

| Viewed: |

1018 Time(s) |

|

|

|

| Back to top |

|

|

AR

Joined: 23 Jun 2005

Posts: 181

Location: Iowa, USA

|

Posted: Fri Apr 07, 2006 10:15 am Post subject: Posted: Fri Apr 07, 2006 10:15 am Post subject: |

|

|

That's a nice transition !

The wedges must fit the Nozzle, right ?

You gotta fix the one that's not standard or you'll have to go through this every time you try something different.

If you need some measurements to help figure which is standard and which is not let me know.

I know Eagle made some Nozzles that were smaller than the Berkeley opening because someone on here had one for sale.

The one I have under buy and sell is standard AT and Berkeley.

.

|

|

| Back to top |

|

|

|