| View previous topic :: View next topic |

| Author |

Message |

Xerophobic

Joined: 23 Jun 2005

Posts: 970

Location: Calgary Alberta, Canada

|

Posted: Mon Oct 10, 2005 9:17 pm Post subject: Impellor frozen to shaft, suggestions??? Posted: Mon Oct 10, 2005 9:17 pm Post subject: Impellor frozen to shaft, suggestions??? |

|

|

I tried to take my impellor off again today with no luck. I had to weld up a tool to grab the groove but it won't budge. This is an aluminum impeller. Can it be heated slightly without distorting it? Its in reeeallly bad shape from the stuff I've run this year and I don't think I will see any impressive numbers with the new motor even if I do sharpen the leading edges of the blades. Im not going to worry about it too muchy but would be nice to clean it up a bit. I'll have to go to SS next season obviously

I think a rock has lodged in the bowl at some point and damaged the trailing edges of the impellor too. One has a dime size part missing from it, DOH!

Where can you get a tool to pull it off? Anyone has a used SS impellor they can part with? Maybe an A?

Cheers

_________________

T-53 , why go up and down when you wanna go round and round???? |

|

| Back to top |

|

|

SouthIdahoGary

Joined: 15 Jun 2005

Posts: 295

Location: Wilder, ID, USA

|

Posted: Mon Oct 10, 2005 10:45 pm Post subject: Posted: Mon Oct 10, 2005 10:45 pm Post subject: |

|

|

Here is a link to American Turbine's download for overhaul manuals. Has one for both an AT SD-309 and Berkeley. Read through them both. Lots of good info. Lots of good info all over the site.

http://www.americanturbine.com/downloads/index_oh_manuals.htm

Link to Rex Marine Jet Pump Tech Tips

http://www.rexmar.com/page115.html

Here is a link to Rex Marine's Jet tools page. They have lots of good info on their site also. You just have to look around. Each page of the catalog area has a link at top right that pops-up a price sheet.

http://www.rexmar.com/page126.html

You can rent one here...

http://cgi.ebay.com/ebaymotors/Impeller-Puller-Jet-boat-tool-Rent-tools-parts_W0QQcmdZViewItemQQcategoryZ26455QQitemZ4542124812

I think you will find lots of electrolysis corrosion build up when you finally get it off. Automotive type pullers just don't seem to cut it for me. I bit the bullet and bought one of the above Rex Marine ones. Takes quite a grip on the impeller and quite a lot of pressure. Heat will help. Aluminum expands a whole lot more and quicker than the SS shaft. I wouldn't worry a whole lot about "ruining" your impeller. (Sounds like it is already toast  ) On reassembly use lots of anti-sieze on the shaft, key, threads, nut and impeller bore. I prefer the silver colored anti-sieze as opposed to the copper. You will know you have enough when it is on the backs of your arms, in your hair and all over the end of your nose. The stuff is insidious. Kind of like sweet and sour sauce when eating Chinese. ) On reassembly use lots of anti-sieze on the shaft, key, threads, nut and impeller bore. I prefer the silver colored anti-sieze as opposed to the copper. You will know you have enough when it is on the backs of your arms, in your hair and all over the end of your nose. The stuff is insidious. Kind of like sweet and sour sauce when eating Chinese.

Stainless impellers are a whole lot easier to get off.....

_________________

"faster, Faster, FASTER until the thrill of speed overcomes the fear of DEATH"#163 "Tuff-n'-Nuff" |

|

| Back to top |

|

|

JR

Joined: 23 Jul 2005

Posts: 81

|

Posted: Tue Oct 11, 2005 1:41 am Post subject: Posted: Tue Oct 11, 2005 1:41 am Post subject: |

|

|

| James if you can drip some CRC or light oil down between the shaft and blade.. Let it soak for a couple of days and then retry .. ( My Blade was frozen to the shaft the only way i got mine off was in this way but with a little heat as well.. Hope it helps.. Cheers JR

|

|

| Back to top |

|

|

BLOWN INCOME

Joined: 07 Jul 2005

Posts: 127

Location: van down by the river

|

Posted: Tue Oct 11, 2005 10:45 am Post subject: Posted: Tue Oct 11, 2005 10:45 am Post subject: |

|

|

| Engine rebuild shops have a cool tool they use to pull the timming gear off the crank....this tool grabbs the small groove on the impeller and will pull a seized impeller off without any dammage.....COMMING FROM EXPERIANCE.

|

|

| Back to top |

|

|

WILSON

Joined: 17 Jun 2005

Posts: 352

Location: Mexico City

|

Posted: Tue Oct 11, 2005 2:45 pm Post subject: Posted: Tue Oct 11, 2005 2:45 pm Post subject: |

|

|

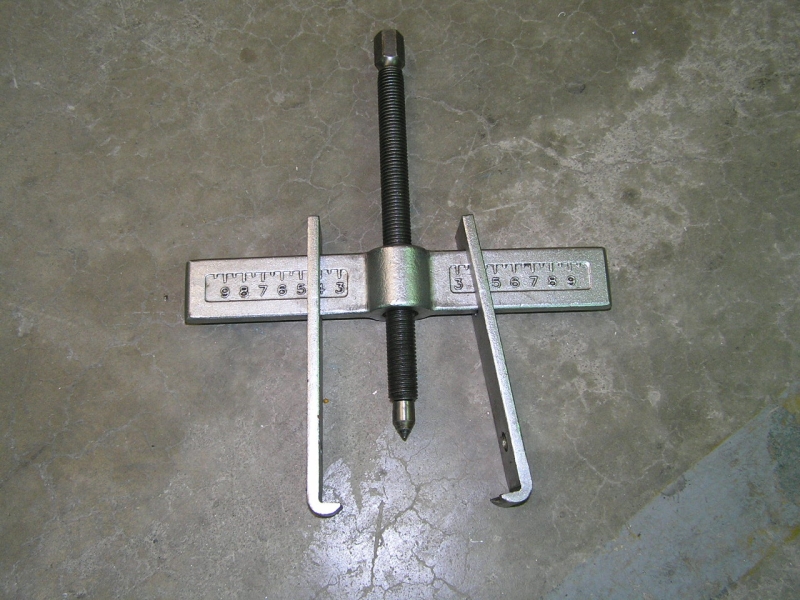

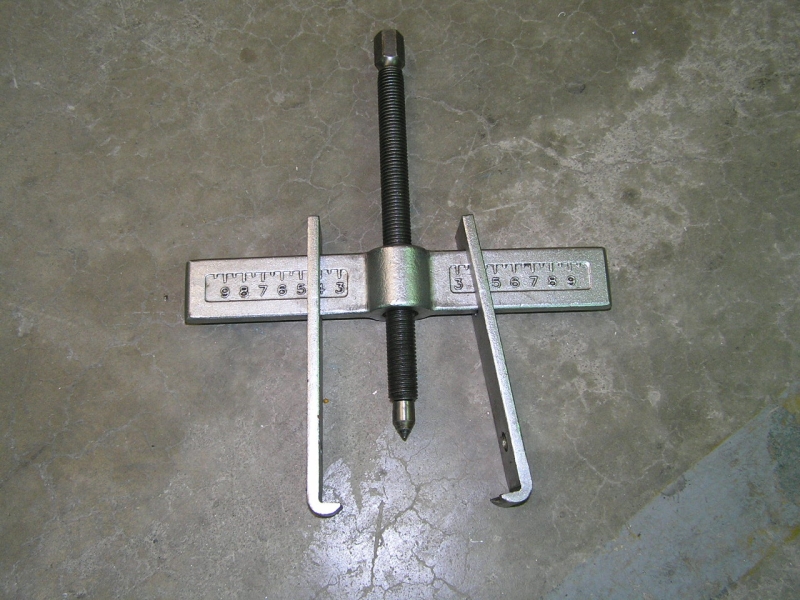

Here´s what you should do:

1) Apply a lot of WD-40 in the shaft and impeller

2) Go to Autozone or Sears and buy an extracting tool similar to the one in the pictures. It is sold as a bearing or harmonic balancer extracting tool.

3) Once you came back from shopping, the WD-40 has made its job and you can apply the tool.

| Description: |

|

| Filesize: |

375.39 KB |

| Viewed: |

30346 Time(s) |

|

| Description: |

|

| Filesize: |

342.81 KB |

| Viewed: |

30346 Time(s) |

|

_________________

Wisdom chases me, but I´m faster |

|

| Back to top |

|

|

AR

Joined: 23 Jun 2005

Posts: 181

Location: Iowa, USA

|

Posted: Tue Oct 11, 2005 2:46 pm Post subject: Posted: Tue Oct 11, 2005 2:46 pm Post subject: |

|

|

Heat is the answer, but you still need a puller ! Even to set a new impeller you will need to take it off and on a couple times.

The Rex puller is probaly the way to go. I use a 8" three jaw puller because I wanted it right now and didn't want to wait for UPS. It took alittle cutting and grinding on the feet to make it work with the groove, but it works well. I use a band clamp around the three arms to hold it in place.

If I could have walked next door and bought a Rex one, I would have !

You need to make a 1 13/16's socket too !

|

|

| Back to top |

|

|

MidwetJetSprint

Joined: 29 Jul 2005

Posts: 160

Location: Chicago Metro

|

Posted: Tue Oct 11, 2005 2:49 pm Post subject: Posted: Tue Oct 11, 2005 2:49 pm Post subject: |

|

|

That tool a little bit of CRC or WD or ?? and a small torch like zinging Rotax rotors off (they use a little bit of lock tite on the crank shaft)

_________________

Old Age and Treachery always Overcome Youth and Skill! |

|

| Back to top |

|

|

AR

Joined: 23 Jun 2005

Posts: 181

Location: Iowa, USA

|

Posted: Tue Oct 11, 2005 2:53 pm Post subject: Posted: Tue Oct 11, 2005 2:53 pm Post subject: |

|

|

Hey Wilson, You own stock in the company that makes that Extracting Tool ?

It says on the side; Made In Mexico

|

|

| Back to top |

|

|

Xerophobic

Joined: 23 Jun 2005

Posts: 970

Location: Calgary Alberta, Canada

|

Posted: Tue Oct 11, 2005 4:01 pm Post subject: Posted: Tue Oct 11, 2005 4:01 pm Post subject: |

|

|

Tks for the info guys. I guess heat is the thing I need but wasn't certain that would not damage the impeller.

I'm only taking this off so I can get at the leading edges of the blades to sharpen them up to get me thru the season. I shouldbe running SS anyway but will worry about that over winter. I assume if I do not remove any shims I can merely reinstall the impeller back on the shaft and not worry about having to 'set it'?

I think its contacted the bowl at some point so I may be into a major pump overhaul anyway. Like I said if it gives me too much trouble I won't worry about getting it off but it would be nice to get some holeshot back and see if it will push me into the high 70's altho Im guessing not the way the trailing edges of the blades look.

I wish I could post pics but don't have access to a cam aat the moment

I will see how it goes tonight. Boat ia at the shop so I have access to a torch

Cheers

_________________

T-53 , why go up and down when you wanna go round and round???? |

|

| Back to top |

|

|

AR

Joined: 23 Jun 2005

Posts: 181

Location: Iowa, USA

|

Posted: Wed Oct 12, 2005 6:43 am Post subject: Posted: Wed Oct 12, 2005 6:43 am Post subject: |

|

|

I guess you could melt it, but you are just going to run the flame around it to get it to hot to touch !

If you get somesort of a puller I'll bet you won't need the heat.......

As for the shims, you may be able to take some out and tighten up your clearance's. I set mine at around .015, but if the nose bearing is bad or the shaft is bent it requires a little more attention.

While it's apart it's worth making it right, it makes alot of performance defference. If you have access to a lath it's pretty easy to "true" your impeller and replace the wear ring. I use the Plastic ones, they work for me.

Looks like Gary already gave you the good information.......

|

|

| Back to top |

|

|

BLOWN INCOME

Joined: 07 Jul 2005

Posts: 127

Location: van down by the river

|

Posted: Wed Oct 12, 2005 3:08 pm Post subject: Posted: Wed Oct 12, 2005 3:08 pm Post subject: |

|

|

| waz this turnin into....pull the thing already.....not exactly rocket science

|

|

| Back to top |

|

|

AR

Joined: 23 Jun 2005

Posts: 181

Location: Iowa, USA

|

Posted: Wed Oct 12, 2005 6:27 pm Post subject: Posted: Wed Oct 12, 2005 6:27 pm Post subject: |

|

|

Depends on how fast you want your Rocket to go !

|

|

| Back to top |

|

|

Xerophobic

Joined: 23 Jun 2005

Posts: 970

Location: Calgary Alberta, Canada

|

Posted: Sat Oct 15, 2005 1:20 pm Post subject: Posted: Sat Oct 15, 2005 1:20 pm Post subject: |

|

|

I got it off on Friday with heat and a 3 jaw puller, ironically the same puller i tried at first(minus the heat)

The impellor looks baaaaad lol leading edges of the blades are shot so Im going to try to reshape them so they at least come to a point but I will be looking for an A SS for next year for sure.

We did weld up the trailing edges a bit too but I seriously doubt the welds will last. We'll see

As long as I can get up on plane a little easier the season is almost done........

Be nice if i could hit mid 70 at least with this thing before I pack it away

Cheers

_________________

T-53 , why go up and down when you wanna go round and round???? |

|

| Back to top |

|

|

|